Materials we use

- Last modified:

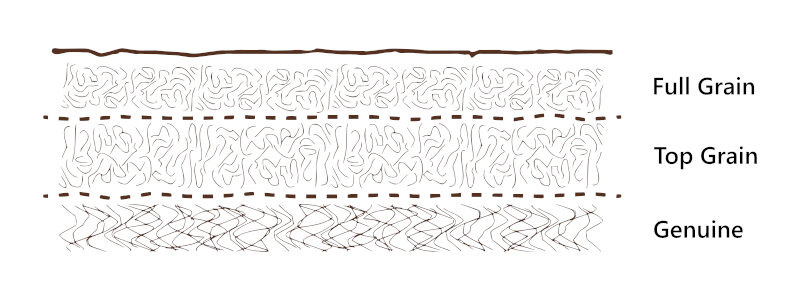

Our belts are made from different types of natural leather. Animal hides are tanned into leather by chemical and mechanical treatment.

Natural leather cross section

As a material, natural leather consists of three layers.

Natural leather cross section

Full Grain: Outer and the thinnest layer of leather, with the strongest fibers. After trimming the hair we get a strong and durable material, sometimes non-uniform because of all the natural blemishes.

Top Grain: Second from the top — also tight and strong. Removing all the blemishes and scars gives a uniform surface.

Genuine Leather: Third from top, thickest, with weaker fibers. Obtained in process of splitting off outer parts, it is used e.g. as a bottom part of bombato belts.

Corrected grain

Sometimes genuine leather is covered with additional materials, lacquers or coatings. It makes the outer layer perfectly smooth and uniform, without any marks or blemishes. We call it corrected grain leather.

Nubuck and suede

Another material in use are nubuck and suede (velvet leather). Nubuck is produced by gentle sanding on the outside, what produces velvet-like nap. Suede, or velvet leather, feels a bit more rough and the nap is thicker.

Regarding construction, we divided our belts into two types: flat belts (classic) — made from a single layer of leather, and bombato belts — two-layered, shaped like lens.